2026 Best Innovations Transforming the Textile Industry?

The textile industry is undergoing a significant transformation fueled by innovative technologies and sustainable practices. 2026 promises to showcase exciting advancements that could redefine how textiles are produced and consumed. As the demand for eco-friendly solutions rises, companies are exploring new materials and production methods that minimize waste and maximize efficiency.

Recent developments, such as bio-based fibers and smart textiles, offer glimpses into a sustainable future. Fabrics that change color with temperature or adapt to user needs present intriguing possibilities. However, not all innovations have immediate practical applications. Some concepts may still require further refinement and testing before widespread adoption.

Despite the promise of modern technologies, the textile industry faces challenges. Balancing innovation with sustainability remains a pressing issue. The need for responsible practices is paramount. As we look to 2026, reflecting on both achievements and shortcomings will guide the journey ahead.

Emerging Smart Fabrics: Revolutionizing Versatility and Functionality

The textile industry is undergoing a transformation with emerging smart fabrics that enhance versatility and functionality. These innovative textiles are engineered with embedded technologies. They can change color, regulate temperature, and even monitor health metrics. According to the latest market report, the smart fabric industry is expected to grow by 33% annually, reaching $4 billion by 2026.

Smart fabrics are not just about aesthetics. They can significantly improve performance. For example, sportswear using moisture-wicking technology allows for better sweat management, improving athletes' comfort. Yet, challenges exist. The integration of technology may lead to increased production costs. This can alienate smaller manufacturers who struggle to keep up with high-tech investments.

Tips: When considering smart fabrics, think about your needs. What functionality do you require? Also, assess the sustainability of these materials. Sustainability remains a concern as the industry shifts toward advanced technologies. Balancing innovation and environmental responsibility is vital. Not all smart fabrics are eco-friendly, and some may come with a high ecological footprint. Being informed can guide your choices in this innovative landscape.

Sustainable Innovations: Eco-Friendly Materials Shaping Textile Production

The textile industry is gradually shifting towards sustainable innovations. Eco-friendly materials are at the forefront of this transformation. These materials reduce the negative environmental impact of production. Natural fibers like organic cotton and hemp are gaining popularity. They are biodegradable and require less water compared to traditional fabrics.

Tips: Consider exploring local organic sources. Supporting these can bolster local economies.

Recycled fabrics are another noteworthy trend. They divert waste from landfills and reduce resource consumption. However, the process still has room for improvement. Not all recycled textiles are created equal. Some may have lower durability. Awareness of these factors is essential.

Tips: Always check labels for recycled content. Look for certifications that ensure quality.

Major challenges persist in adopting eco-friendly materials. Sourcing these fibers can be inconsistent. The production cost often remains high. Brands and consumers must advocate for better practices. Awareness and education will drive demand for sustainable innovations in textiles.

2026 Innovations in Sustainable Textile Production

This chart illustrates various eco-friendly materials that are transforming the textile industry in 2026. Each material's impact is measured based on its adoption rate and sustainability score.

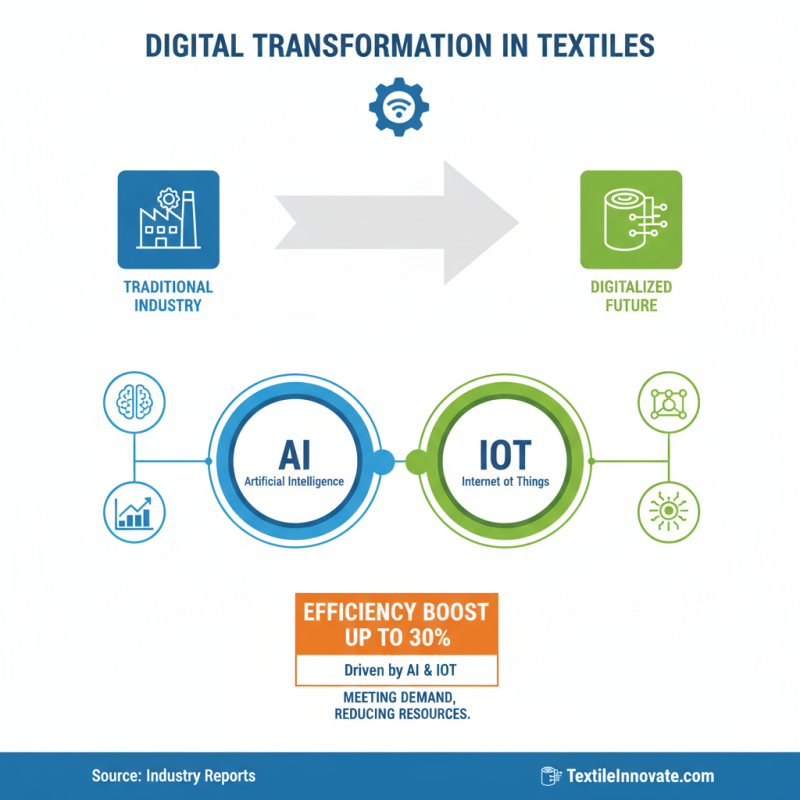

Digitalization in Textiles: The Impact of AI and IoT on Manufacturing

The textile industry is experiencing a profound shift due to digitalization. Technologies like AI and the Internet of Things (IoT) are at the forefront of this transformation. Reports indicate that AI can improve production efficiency by up to 30%. This is significant for manufacturers aiming to meet rising demand with fewer resources.

IoT devices enable real-time monitoring of production lines. For instance, sensors can track machine performance and warn about potential failures. This predictive maintenance can reduce downtime by 25%, according to industry analysts. However, integrating these technologies is not without challenges. Many companies struggle with data management and require skilled personnel to interpret information accurately.

Digitalization also influences consumer behavior. Shoppers increasingly expect personalized products. AI algorithms analyze customer preferences to create tailored textiles. Yet, this raises questions about data privacy. The industry must navigate these dilemmas while pursuing innovation. Balancing technology with ethical considerations remains a crucial task for textile manufacturers.

3D Printing in Fashion: Customization and Efficiency in Textile Design

3D printing is revolutionizing the textile industry. It offers unprecedented customization and efficiency. Designers can create unique pieces tailored to individual preferences. Reports show that the global 3D printing market in textiles could reach $1 billion by 2025. This growth indicates a strong shift towards personalized fashion.

With 3D technology, materials can be layered to form complex designs. This method reduces waste significantly. Traditional fabric production can waste up to 15% of materials. In contrast, 3D printing uses precisely what is needed. However, the technology is not without challenges. It can be expensive to set up. Some designers may feel overwhelmed by the learning curve.

Moreover, there are concerns about the environmental impact of certain materials used in 3D printing. Not all inks and filaments are sustainable. Industry leaders highlight the need for biodegradable options. Without a focus on sustainability, innovation can lead to new problems. As the market evolves, these issues must be addressed. The future of textile design relies on balancing creativity with environmental responsibility.

Biotechnology: Advancements in Fibers and Finishing Processes

Biotechnology is reshaping the textile industry in significant ways. Innovations in fiber production have led to the creation of more sustainable materials. For instance, bioengineered fibers can potentially reduce the reliance on traditional petroleum-based products. These developments are exciting, but some key challenges remain. The processes involved can be complex and require extensive research.

Finishing processes also see advancements through biotechnology. Treatments can improve fabric performance, making them more durable and water-resistant. Enzymatic processes, for example, can replace harmful chemicals in textile finishing. Yet, these biotech solutions may not always be cost-effective for every manufacturer. There is often a trade-off between sustainability and production costs.

While the outlook is promising, reflection is necessary. The impact of biotechnological advancements must be measured against environmental footprints. Not every innovation is without drawbacks. As the industry moves forward, it must balance efficiency with ecological responsibility. The future of textiles lies in finding that equilibrium.

Related Posts

-

2026 How to Master the Dyeing Finishing Process for Textiles?

-

2026 Top Dye Application Techniques for Vibrant Results?

-

2026 How to Use Spray for Textile Effectively in Your Projects?

-

Understanding the dyeing process for the top fabrics of 2025

-

Digital Transformation Best Practices in Textile Industry Process?

-

2025 How to Master the Textile Finishing Process for Optimal Results